Extended Closure

Sort of along those those lines, I was wondering if they have to change from alluminum over to using more traditional steel parts on the trains, will it add too much weight and then cause the launch to be a problem? Kind of doubt it will be that drastic of a weight change, but who knows?

-Matt

For all we know (which is essentially nothing), it could be that they're redesigning the geometry of the assembly to make it more robust. I even thought, after seeing pics of them at IAAPA, that they looked a tad scrawny. One thing is for sure, we'll know what was done once they start reassembling things and start testing.

-Adam G- The OG Dragster nut

I don't understand why anyone is worried about aluminum. Airplanes are aluminum. Both of my cars are entirely aluminum, carrying heavy-ass batteries and having to deal with a whole lot of torque when the light turns green. The strength to weight ratio favors aluminum over steel.

Jeff - Advocate of Great Great Tunnels™ - Co-Publisher - PointBuzz - CoasterBuzz - Blog - Music

I think 90% of people instantly think of the type of aluminum that is most commonly used in everyday applications and how pliable it is. I'm guilty of thinking the same as I work with "soft" aluminum every day at my job. A simple google search was all I needed to put any fears to rest. It would be interesting to know just what grade is being used with TT2 and if they're changing the grade with the wheel assemblies.

-Adam G- The OG Dragster nut

In another lifetime, I worked on an iron-pouring line at a General Motors plant in Defiance, Ohio. It was an intense summer job working the 3rd shift pouring engine cores.

That line I stood on and many like it don't exist and haven't existed for well over 2 decades because of the rise of aluminum in almost every aspect of auto manufacturing.

I don't know what grade is being used on TT2, but I have full confidence that in 2024 it's easily a preferable choice over steel in every conceivable way.

Promoter of fog.

Jeff:

Both of my cars are entirely aluminum...

That's not accurate, at least as far as I can tell. This may be something of a technicality on Model S, which limits the use of steel (UHSS) to the B-pillar, but steel is used far more extensively on the Model 3, basically around the entire cabin, and also on Model X, where steel is used on the A- and B-pillars and connecting roof rail. Then there's Model Y, which is almost entirely steel, with aluminum in use only for the closures, which is also the case for the vast majority of passenger vehicles produced today. The point being, steel is used where the design calls for more strength (UTS>~1000MPa) than aluminum can provide (UTS<=~500MPa).

Generally speaking, aluminum's high strength-to-weight ratio is beneficial for vehicles where a primary design goal is efficiency in terms of MPG/MPKWh, but that characteristic isn't necessarily useful in the case of a roller coaster chassis. I'm not saying the use of aluminum in the chassis and/or assemblies (are these also aluminum?) is a problem, but fuel/energy efficiency isn't necessarily the characteristic that should be driving coaster train design. Hell, the Zamperla trains could conceivably have less "shimmy" with a much heavier steel chassis, as some of the "shimmy" energy might transfer to the track/structure in that case, but that's uninformed speculation on my part.

The point is, aluminum being the ideal choice for Use Case A doesn't make it a good choice for Use Case B.

Brandon

Aluminum has one big fault in specific uses, though... Endurance limit. Basically, how many 'cycles' a material can withstand without fatigue failure.

Steel will hit a limit and basically not fatigue any further when designed properly under the same loading. Aluminum continues to weaken with repeated cycles in which much smaller loading can cause fatigue failure. This is one of a few reasons why aircraft have life spans per pressurization cycles, for example.

It's just something to consider in the design is all (and basically be overbuilt to where aluminum will be cycled and heavily loaded millions of times). Composites are a great option as well, which is why new aircraft are so heavily reliant on it... No endurance limit, strength to weight ratio, etc... The 787 and A350 are over 50% composite by weight, for example. But they still use plenty of aluminum, steel and other exotic alloys.

But again, engineers (should) know this and design for it accordingly with analysis, margins, etc... It's just not always as simple as aluminum > steel, different tools for different jobs.

-Steve

djDaemon:

Then there's Model Y, which is almost entirely steel...

That's what I have, and this is not true. I had a nice chat with one of the guys doing body work at the shop where we had our 3 repaired. The frames (columns) around the doors are steel, but the entire rear third of the car frame is a huge, single cast piece of aluminum. The front third is also aluminum, though made from many pieces (which the guy indicated makes it way easier to repair... hit the back end in a certain way and it's pretty much totaled). The body panels I'm not sure... the doors are definitely aluminum, not sure about other parts. So perhaps "entirely" was the wrong word, but the "gigacasting" alone, as a matter of mass and volume, makes it mostly aluminum.

djDaemon:

The point is, aluminum being the ideal choice for Use Case A doesn't make it a good choice for Use Case B.

My point is that I'm not aware of any metallurgists here who could determine that it's not a valid use case for a coaster train. But to dismiss it just because, when it's used in one of the safest cars in the world, doesn't make a lot of sense.

Invertalon:

This is one of a few reasons why aircraft have life spans per pressurization cycles, for example.

For sure, and it's also worth noting that they last for decades under nearly continuous use. I was curious about those limits, and the US regulations put a 737 service life at 75,000 cycles. Most of the midsize Airbus models are 48,000, and I'm surprised by that difference. I'm sure it's just current public perception, but I expected the Airbus planes to be more robust.

Jeff - Advocate of Great Great Tunnels™ - Co-Publisher - PointBuzz - CoasterBuzz - Blog - Music

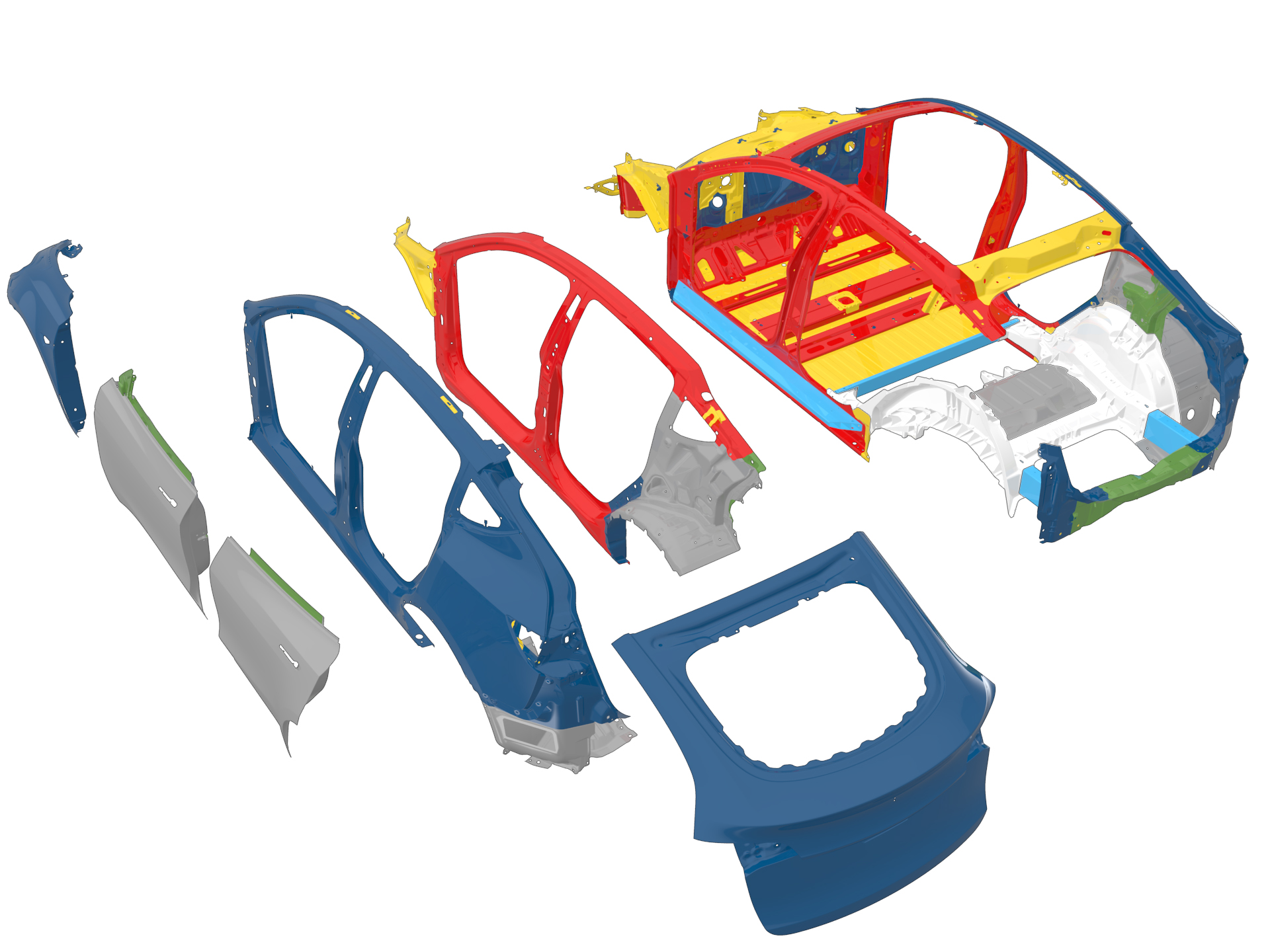

So now my curiosity has been sparked. Found this Tesla collision repair procedures manual that has a breakdown of the various metals that are used. The color coding makes it easy to see what is what.

Jeff:

That's what I have, and this is not true.

Tesla's official Model Y Emergency Response Guide, linked above, disagrees:

Now that document may only refer to body areas needed to gain access to the cabin, but Tesla's official Model Y Collision Repair Procedures Manual shows a complete breakdown of the body, see below. The aluminum components are light gray, dark gray, light blue, and dark green. So, the closures, door sills, inner quarter panels, a couple crossmembers, and the cast subframe in the rear. The steel components are blue, yellow, and red:

Brandon

That's not disagreement, I just don't think you're looking at it in totality, nor have you seen it up close. It's exactly what I described: The sides are steel, along with apparently the trunk (which explains why I see magnets on them). The floor is pretty thin, and I suspect more of a barrier from the battery than structural. (The battery is sandwiched in aluminum, and has a titanium plate under it.) Find the teardown videos from Sandy Monro. That single cast piece is huge, and replaces 70 individual parts. You can actually see it directly in the trunk. It's still more aluminum than not.

Jeff - Advocate of Great Great Tunnels™ - Co-Publisher - PointBuzz - CoasterBuzz - Blog - Music

Silver train is reportedly going to have all it's bogies back on at some point tonight. Zamperla and CP maintenance really moving at light speed.

-Adam G- The OG Dragster nut

That photo doesn't give a good look at the bogies, unfortunately, but I imagine we'll see them in the coming days.

I wonder where the parts are coming from. The whole industry is pretty weird about fabricating stuff, like what they make is so exotic that only specific companies can do it in far off lands.

Jeff - Advocate of Great Great Tunnels™ - Co-Publisher - PointBuzz - CoasterBuzz - Blog - Music

Take a fall from 100 feet up on a carabiner or one of these and you'll have a nice appreciation for how strong aluminum can be:)

TTD 120mph:

Silver train is reportedly going to have all it's bogies back on at some point tonight.

Promoter of fog.

The Zamperla crew after being on site and working nonstop since the closure:

-Adam G- The OG Dragster nut

No where near an expert, but...

Knowing about the fatigue life of aluminum, I wonder if it's because aluminum tends to be a more brittle material than steel. That is, steel will bend while aluminum will crack. Then too, we're also talking about the difference between forged, cast, and machined parts. I think we're seeing a lot more machined components on the TT2 trains than we normally see on coaster trains, which more often use forged or cast steel parts.

("forged" as in "pieces welded together"; not as in "shamelessly copied". We're not talking about Golden Horse here.)

--Dave Althoff, Jr.

/X\ *** Respect rides. They do not respect you. ***

/XXX\ /X\ /X\_ _ /X\__ _ _____

/XXXXX\ /XXX\ /XXXX\_ /X\ /XXXXX\ /X\ /XXXXX

_/XXXXXXX\_/XXXXX\_/XXXXXXX\_/XXX\_/XXXXXXX\__/XXX\__/XXXXXX

Closed topic.